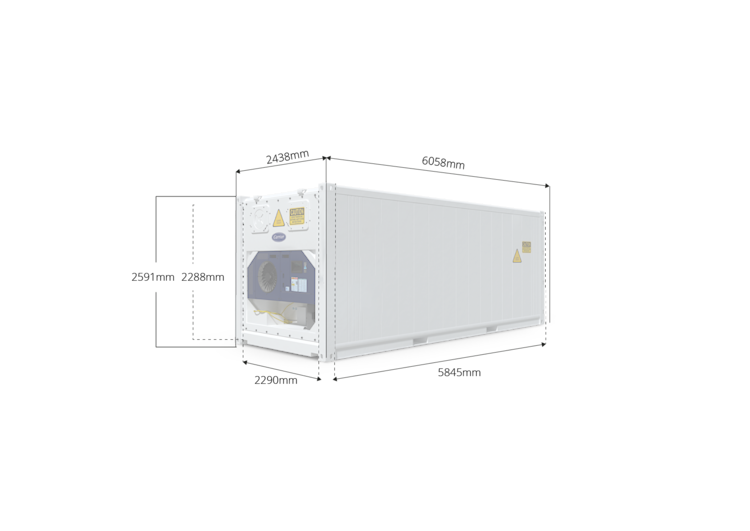

Construction

- The container has a metal frame, with ISO standard corner fittings for lifting by machine or crane. Containers are also equipped with forklift pockets – they can be used for moving empty containers.

- Walls and the roof are made of stainless steel sheet and filled with foam of 8 and 10cm thickness. The floor is insulated from below.

- The container has doors on one side, opening to the sides, with closures compliant with the ISO standard. It can be secured with a padlock at several points.

Equipment

- Aluminum grating on the floor.

- Walls and ceiling made of stainless steel.

- Factory drain holes in each corner allowing for the discharge of accumulated liquids.

- Modern and user-friendly refrigeration unit with the ability to control temperature every 0.5°C

- Possible installation of energy-saving LED lighting.

- Possible installation of a protective curtain.

- Optional purchase of a ramp for the container.

Application

Refrigerated containers, despite their name, operate across a wide temperature range and find many applications in various industries - wherever strict control of storage and transport conditions is needed. Their significant advantage is the absence of huge costs associated with constructing stationary refrigerators, as well as a minimum of formalities since the containers are not permanently connected to the ground. They are also accepted by health inspection authorities.

- Cosmetic Industry

- Pharmaceutical Industry

- Meat Industry

- Fish Industry

- Chemical Industry

- Food Industry

- Catering